Welcome to Southern Turbine & Energy Solutions Inc.

"Our goal is to help each client and exceeds your expectations"

About Us

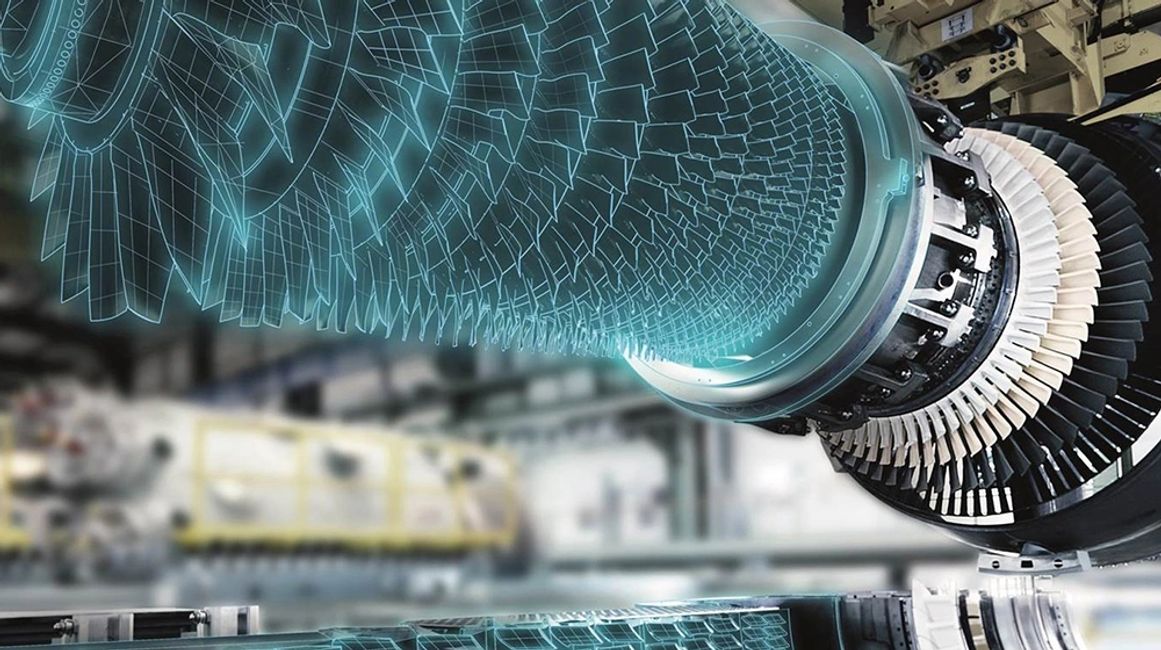

“STES Has The Knowledge & Experience On Steam, Gas & Hydro Turbines Needed To Maintain Your Capital Investment In Optimal Operational Condition.”

Our company specializes in providing technical specialists and project management personnel to our power generation, refinery and oil and gas industry clients. Staffing is available for all phases of a project, including development, engineering, construction, commissioning and ongoing operations and maintenance. Whether the project is long-term or short-term, all of our employees and consultants are carefully screened and selected to assure the highest-quality staff is available at all levels.

From start-up and project scheduling through training and post-completion manuals, Southern Turbine & Energy solutions provide complete guidance on all aspects of your project. We can offer our services in any location countrywide with a qualified staff and service. Our main capital is the human resource, offers a dependable consultants-one to rely on to save a customer time, money and assistance in crisis situations.

Services

OPERATION & MAINTENANCE

Southern Turbine & Energy Solutions are focused in the power generation, refinery, oil and gas industry, with advanced technologies, updated staff and efficiency methods.

We can give you all O&M strategies starting with the routine maintenance on equipment to full control of plant operations, STES operations and maintenance services are packaged to deliver the specific services each customer needs. Our skilled operations and engineering teams provide turbine maintenance solutions to minimize downtime, increase availability and reduce the overall operating costs of your facility. We have experience managing OEM equipment including gas turbines, generators and transformers across all phases of project development, no matter the size of the project or where the customer is, We can provide capabilities cover Construction supervision & inspection, consulting, balance-of-plant systems including boilers, heat recovery steam generators, condensers, boroscopic inspections, routine or corrective inspections and repairs, Installation, tuning and removal of mechanical equipment, SCADA/remote well control system design & integration, fuel handling systems, precipitators, ash handling systems, water treatment plants, electrical & control systems, switch gear, all fluid and gas processes and core rotating shaft equipment, Pre-operations planning.

STES operates and supports our customer’s projects with the same corporate commitment we apply in our own company. We treat your business enterprise as if it were our own and adhere to the concept of performance-based compensation. We pledge to provide the technical, managerial, and administrative services required in the most economical fashion possible to maximize profitability, ensure the highest safety standards and exceed environmental requirements.

We are offered many tools as an integral part of our service, such as specialized configuration and inspection equipment to make sure unit and process systems function properly. The scope of our services can be adapted to satisfy the specific maintenance needs, from the supply or technical support to the full management of the operational interruptions, including the re-starting of the plant, Operators also detect potential and actual problems and take corrective action to prevent the interruption of system operations. We can provide these services by programmed maintenance or when an emergency occurs at the plant.

With our extensive base of technical staff, instruments and project administrative management, we can offer the option of operating the plant if the project’s scope requires the same guaranteeing a level of efficiency in the operations.

“From projects in the US, Caribbean, South America and in the Middle East, we maintain an international staff group of experienced professionals in order to offer an extraordinary balanced of approach-ability and superiority services.”

Services

TECHNICAL ASSISTANCE

“We can offer all services and training solutions in English, Spanish, and other local languages from EEUU, South America, Europe, Asia and the Middle East.”

The main goal of technical assistance is assisting, recommending and transferring knowledge to the permanent plant staff. This technical support can be implemented in both the operations and the maintenance areas. With the assistance from specialists in the area, specific programs can be created to optimize routine and corrective maintenance protocols, plan the parts to be used in the plant shutdown, evaluate safety procedures, monitor the plant’s operation and controls, and analyze the historical data to determine the tendencies of the plant’s equipment.

The experts appointed to this task can assist you in plant shutdown for major maintenance or to provide you with evaluation reports on the effectiveness of the plant in its operation and maintenance processes.

Services

INSTRUMENTATION AND CONTROLS I&C

Our technicals are capacitated to perform corrective and preventive maintenance, calibrations on electrical switchgear, process controls, transmitters, and gauges and other instrumentation and control equipment in accordance with plant and vendor procedures. They have skills routine and advanced trouble shooting activities. Implement plant modifications and improvements as assigned. They have a knowledge of electrical circuits and machines and capable of working on low and high voltage switchgear, including understanding of instrumentation and controls for Gas and steam turbines and steam generating systems, are be able to troubleshoot and diagnose problems in systems, read and interpret blueprints, equipment specifications, and vendor service manuals, have ability to understand, develop and/or complete records and reports as required, are understanding or awareness of Digital Computer Control Systems. Our Workers read and understand blueprints, schematics and vendor supplied instruction manuals, also demonstrating good analytical skills.

“We can offer all services and training solutions in English, Spanish, and other local languages from EEUU, South America, Europe, Asia and the Middle East.”

COMMISSIONING

Commissioning is an important stage in the existence of any facility. The process may be thought of as a series of vital checks that are undertaken before actual operation begins. Our complete commissioning services can play an important role in minimizing project risks and achieving performance goals right from the start.

At STES, it’s our job to prove the integrity of all systems, identifying and correcting design and construction errors along the way. Our complete ability helps our clients meet a host of challenges that progress from a project’s very beginning, such as cost control; schedule adherence; regulatory, safety and environmental compliance; and operational performance.

Obviously, the safe, efficient operation of each facility is our target. Concerning that end, we assume complete responsibility for commissioning, whether we start in the engineering department, provide knowledge in the construction yard or mobilize to a remote area.

We offer the following commissioning services:

- Consulting (project controls development, project certification)

- Supervision and engineering (all disciplines)

- Provision of technicians (field, mechanical, instrumentation, electrical)

- Materials, logistics & HSE/permit-to-work ("PTW") coordination

- Punch list coordination

- Certification & handover

POWER SOLUTIONS:

STES manages standard procedures and experience to offer constant trajectory, turnkey power solutions on time and on budget.

STES offers utilities, self-governing power producers and operators of industrial process plants with integrated solutions. From front-end project design to support throughout the life cycle of your asset, our knowledge of gas turbine technologies, operations & maintenance and power plant construction enables us to develop, operate, maintain and expand the capacity of your power facility.

STES integrated design plan allows us to deliver combined Engineering, Procurement and Construction services to construct power plants in cogeneration, combined cycle and simple cycle gas turbine configurations.

Some of our Engineering, Procurement and Construction services include the following:

- Viability studies

- Surveys for new projects

- Theoretical & specified engineering

- Procurement of major equipment and balance of plant

- Project & construction management

- Start-up & commissioning

- Performance testing

- Installation & commissioning manuals for OEM equipment

- Electrical & control systems

Our staff of qualified, experience Engineering has more than over 40 years of combined advanced, and working in the power generation industry servicing turbo-machinery, we support customers globally. No worry what your gas turbine or thermal power needs, we offer the knowledge and time-tested progressions to keep your project moving forward successfully.

“From offering critical operations input during SUPPORT to proving that all systems work with one another to estimating manpower necessities with your facility’s operations managers, STES has an complete commissioning know-how to help your facility get up and running safely and efficiently.”

OUR PROJECTS

We worked with HPI at the Commissioning Support at Austin Greek Power Plant, The project upgraded and re-commissioned the liquid fuel system and only the natural gas fuel system was in use. Our work was oriented to the area of instrumentation and control. The project required much demolition work, including removing complete panels and junction boxes. The original cabling within the turbine enclosures was installed at the factory as part of the original package. When the demolition began, workers quickly discovered control wiring mixed in with power cabling that terminated at the motor control center—no longer an acceptable wiring practice. Instead, all of the control and power cabling was run in separate trays from the marshaling cabinets to the field to eliminate the possibility of “cross talk” between adjacent wires. Digital and analog signals were separated into individual cables for the same reason.

PROJECT 01

The existing control system was completely removed and replaced with a new controller for the Turbine Control system. The controller sets for the new Turbine Control Systems are based on Allen Bradley Control Logix PLC. This PLC contains the software for the Gas Turbine controls such as Remote start, stop and auxiliary system sequencing. To reduce the amount of on-site wiring required all the terminals, fuses, relays and conduits are supplied mounted on sub-panels.

PROJECT 02

The existing control system was completely removed and replaced with a new controller for the Turbine Control system. The controller sets for the new Turbine Control Systems are based on Allen Bradley Control Logix PLC. This PLC contains the software for the Gas Turbine controls such as Remote start, stop and auxiliary system sequencing. To reduce the amount of on-site wiring required all the terminals, fuses, relays and conduits are supplied mounted on sub-panels.

PROJECT 03

In 2003 a set of 2X GEC EAS1 generators were installed in a water treatment plant in the Karkh region of Iraq, about 17 miles north of Baghdad in Tajii. Two years later in 2005, the power plant was severely damaged by a by an incident which left the building’s circuitry, switchgear, circuit breakers, generators, auxiliaries and air-conditioning systems at the water treatment facility completely inoperable. The equipment that remained intact eroded due to the extreme environmental conditions of the Iraqi desert. Without the facility, roughly 6 million people in Baghdad were left with few choices for potable water. In 2008, we worked with HPI of Houston who was awarded a contract as part of a project run by the U.S Army Corps of Engineers and the Government of Iraq to refurbish the turbines and associated controls. To restore plant operation the project required a multi-disciplined, multi-cultural team to work together through harsh conditions, seven days a week for six months.

CONTACT US

INFO REQUIRED